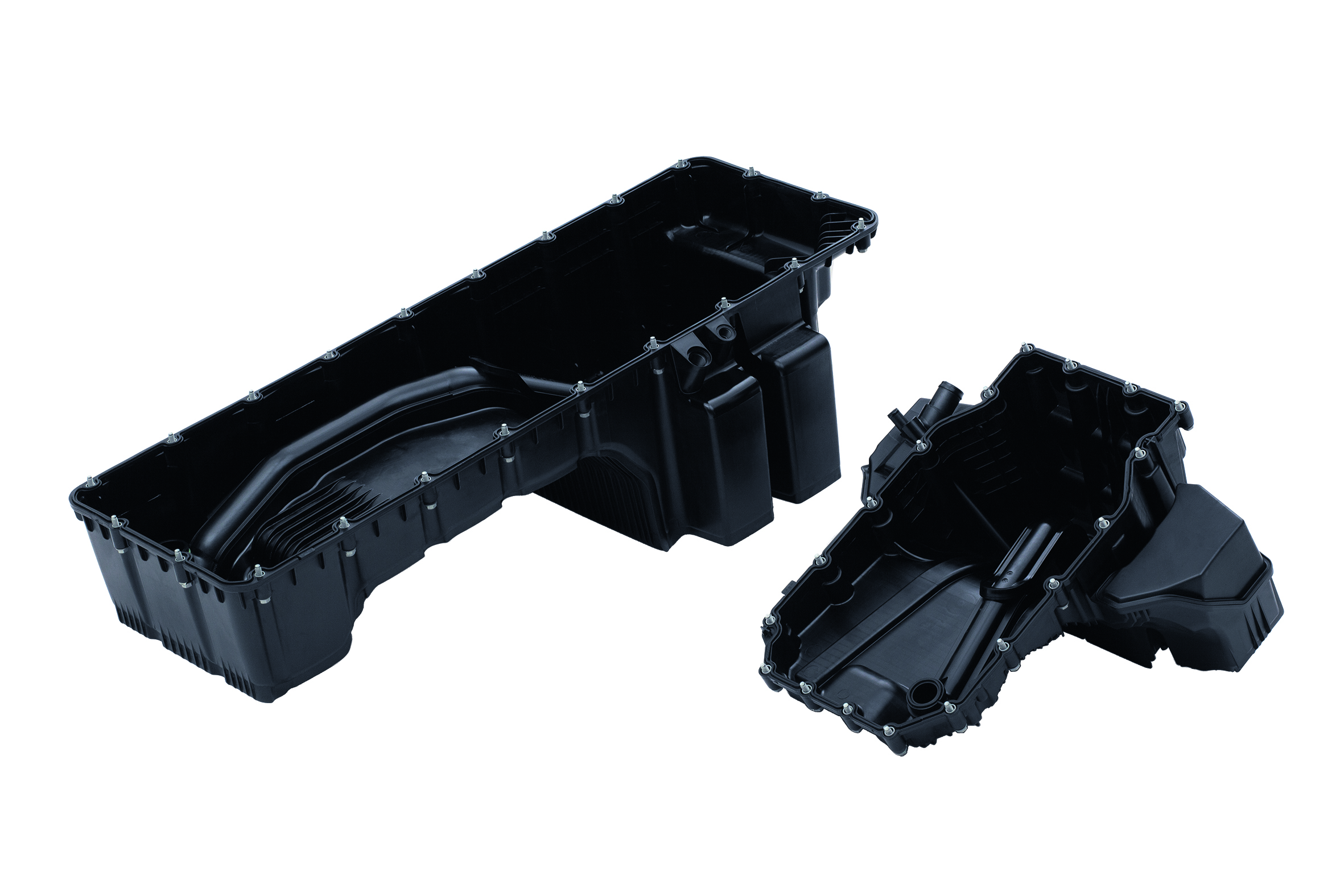

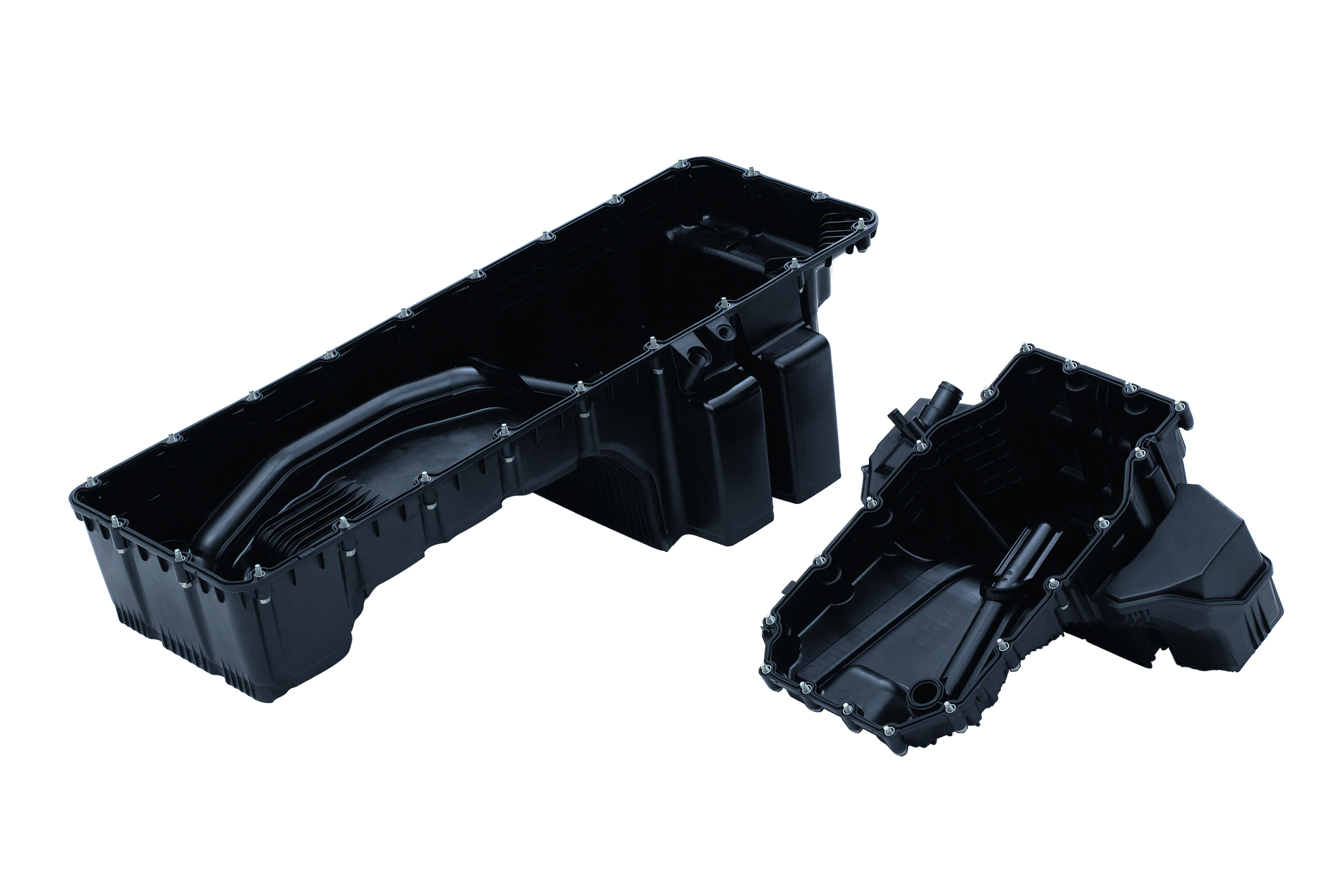

Lightweight Plastic components

Multifunctional, durable and efficient.

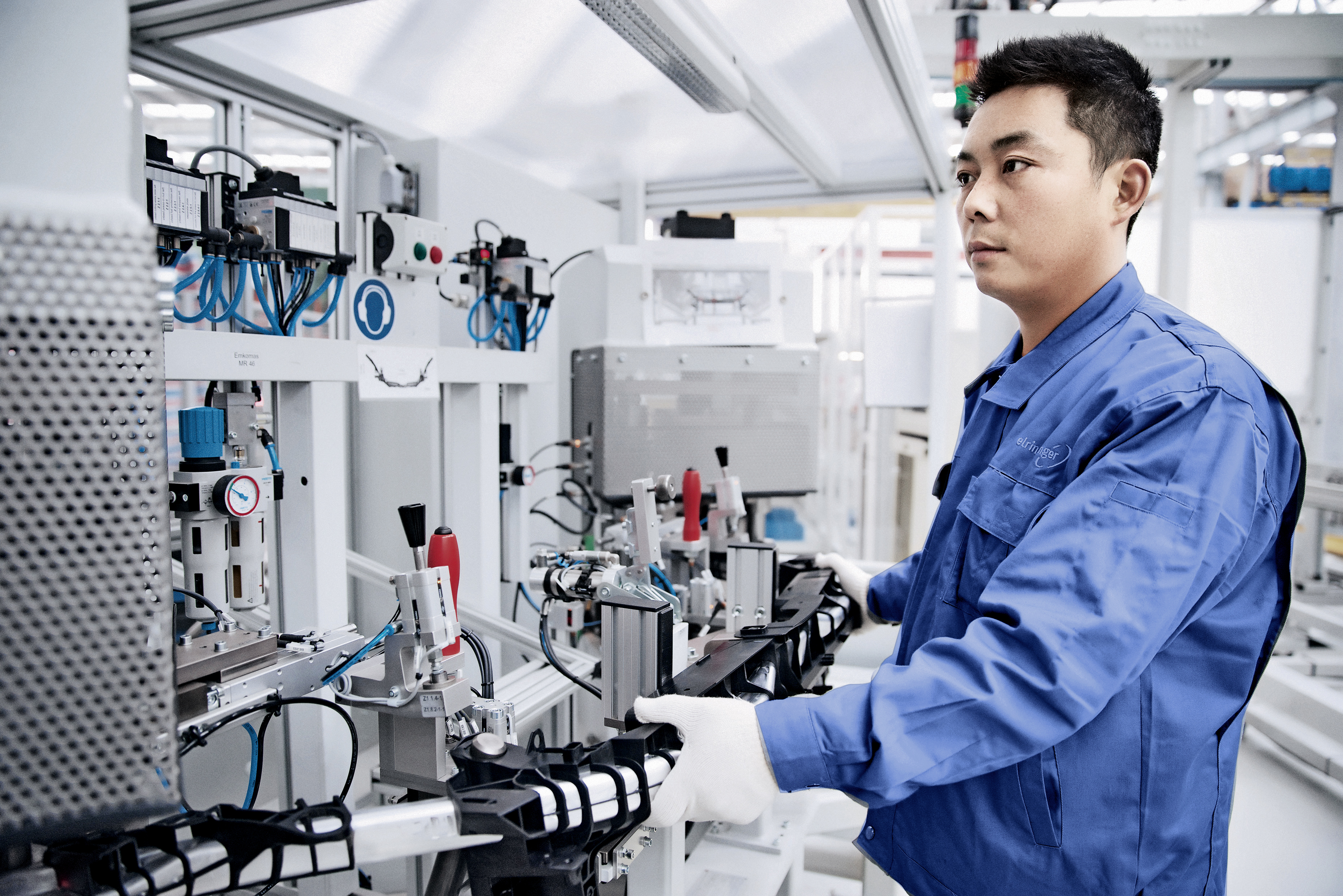

Industry requirements regarding functionality, safety, stability, environmental compatibility, design and comfort are exacting. With its comprehensive expertise in materials, processes and fabrication, ElringKlinger is in a position to meet this challenge. Drawing on many years of experience, we offer lightweight components for drive train and car body.

At ElringKlinger, intelligent lightweight design means:

- Reduced material use

- High cost-effectiveness

- Integration of numerous functions

- Function test of complete module

- Improved NVH characteristics

- Design freedom

- Shorter development times

- Safe, simple assembly

- Recycling capability

The first lightweight plastic component went into serial production at ElringKlinger at the end of the 1990s. Today, we are producing around 10 million units a year – and this volume is set to grow.

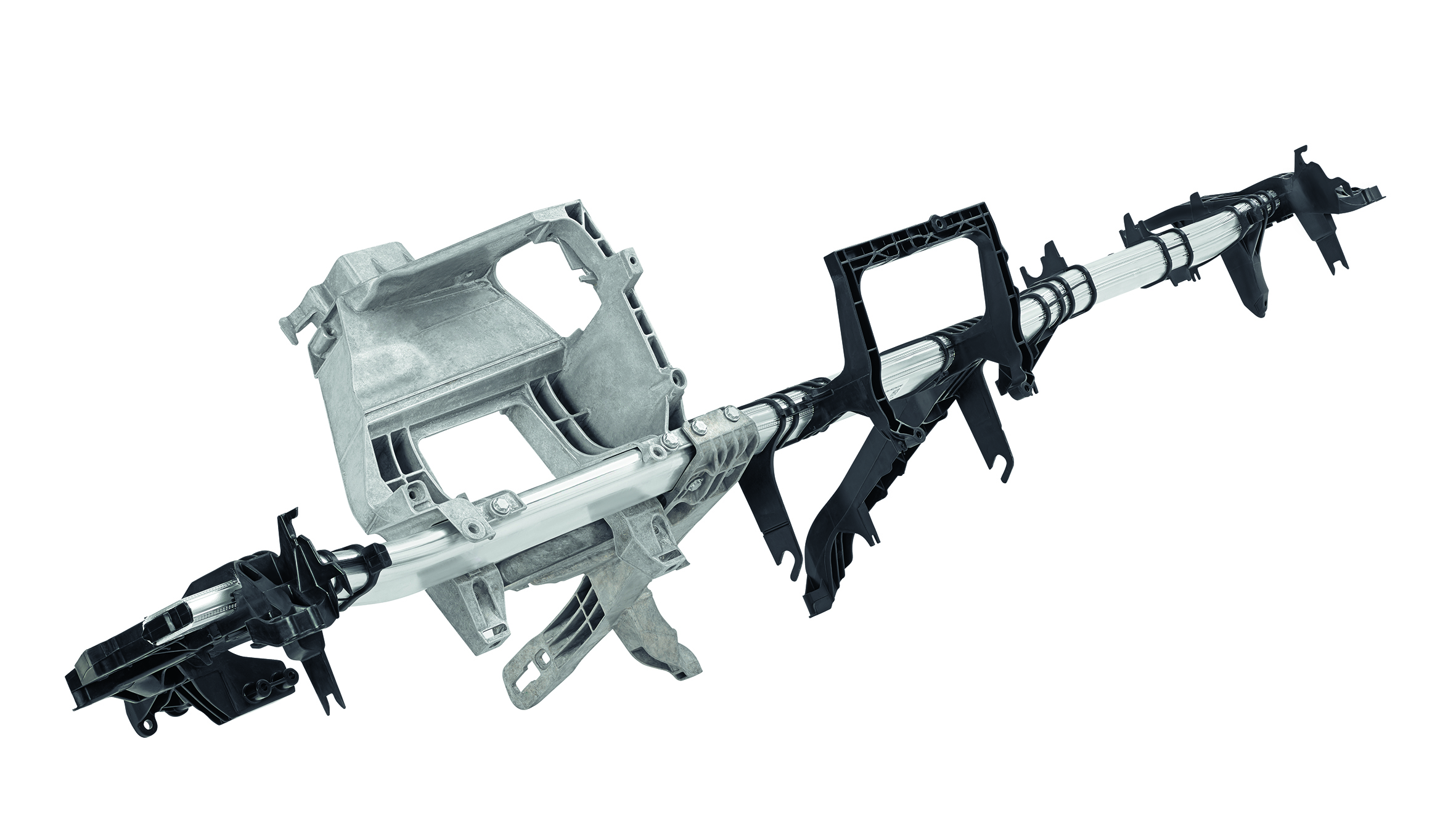

Lightweight plastic components for car bodies. Made to be tough.

Modern vehicles have to meet very exacting requirements with regard to functionality, safety, stability, environmental compatibility, design and comfort. By systematically exploiting our comprehensive expertise in materials, processes and fabrication, we can also offer customized lightweight components for vehicle bodies. These include cockpit cross-car beams and front-end carriers made of polymer-metal hybrids, engine and transmission mounts in glass-fiber-reinforced thermoplastics and structural components based on organo sheet technology.

For more information concerning our lightweight plastic components, please go to: https://www.elringklinger.de/en/products-technologies/original-equipment...

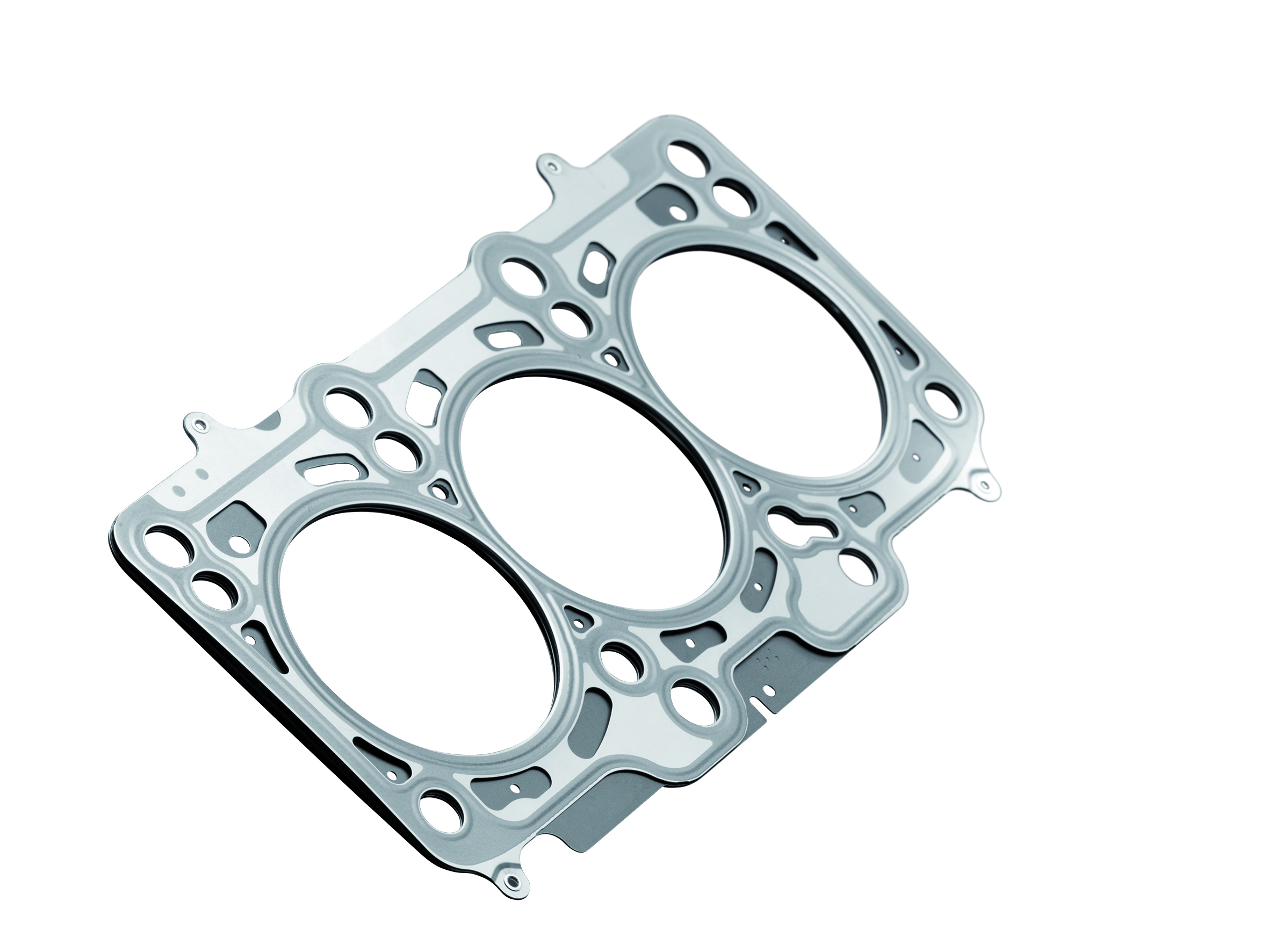

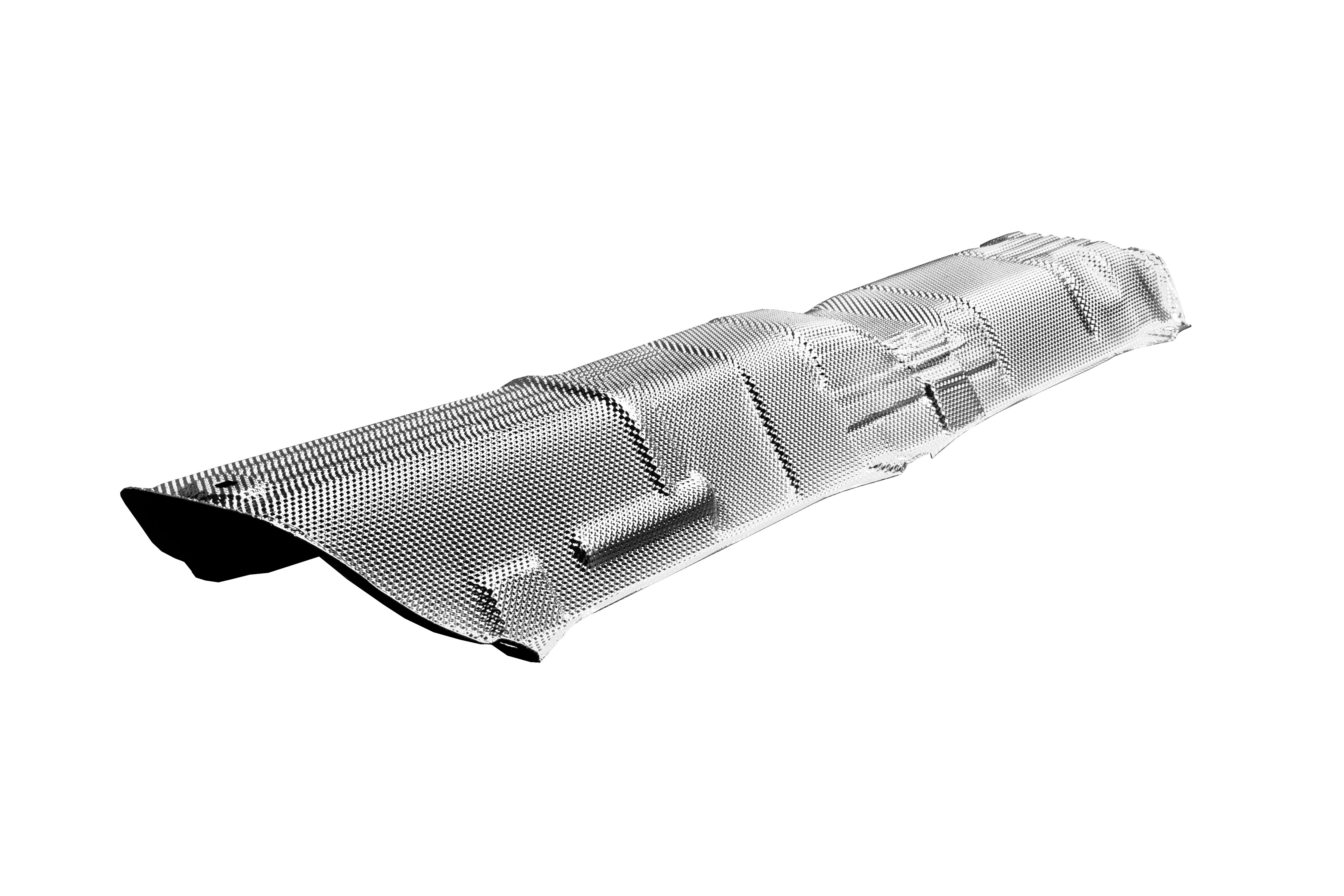

Shielding Systems

The areas of a vehicle that develop high temperatures call for an effective thermal shielding solution. In addition, noise protection standards are becoming more and more demanding.

In its capacity as technology leader and major supplier of shielding parts, ElringKlinger always has the right solution to meet any challenge within these areas. We develop sophisticated shielding solutions designed to help bring vehicles in line with increasingly stringent legal requirements worldwide.

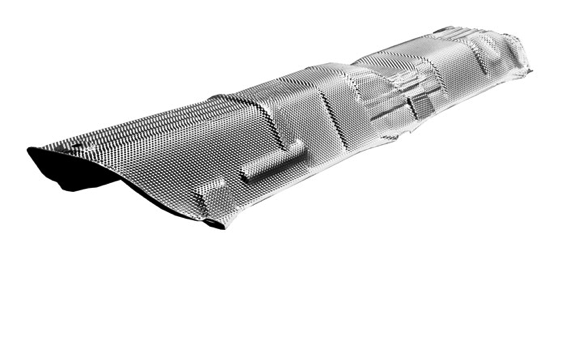

ElroTherm™ shielding systems. Thermal and acoustic management for the entire vehicle.

The management of temperatures in modern vehicles is becoming increasingly complex. Tightly packed components, engine encapsulation, minimal cooling air flows, catalytic converter technology and exhaust gas turbochargers result in high temperatures in the engine compartment, across the exhaust system and within the area of the underbody. At the same time, there are a growing number of temperature-sensitive components that have to be protected from heat. The demands on shielding technology have been increasing along with the number of applications. Thermal and acoustic shielding systems help engine and exhaust systems to function safely and reliably. In the process, they also contribute to enhanced driving comfort and environmental protection.

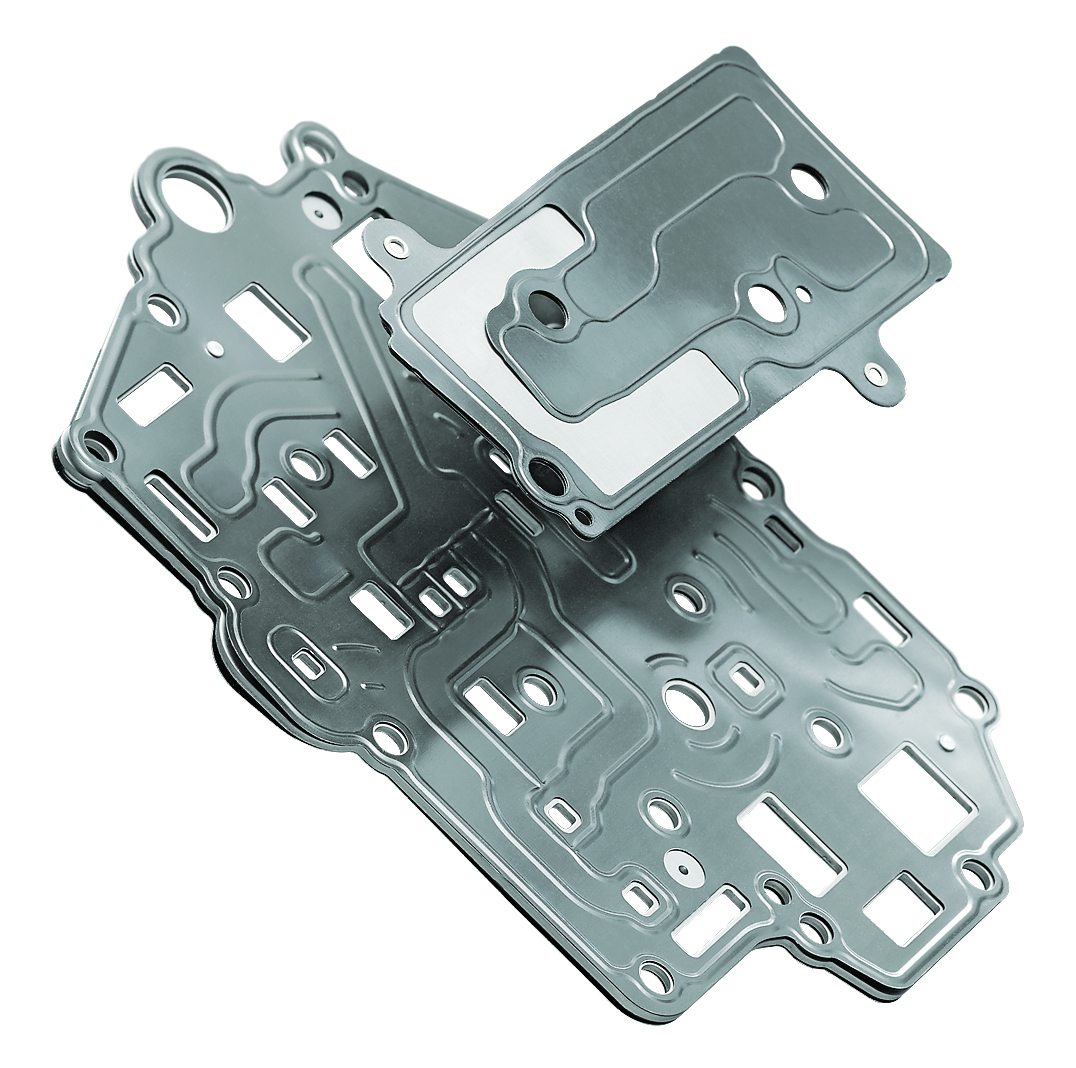

ElroCoustic™ shielding systems. Sound solutions Lighter, quieter, better performance.

The requirements made of modern motor vehicles are becoming more and more demanding. Long gone are the days when all that mattered were emissions, fuel consumption and preservation of resources. Today, regulations governing traffic and ride noise, for instance, are equally stringent. In fact, EU committees are currently discussing significant reductions in noise thresholds for new cars – to become mandatory as of 2019.

The challenge for manufacturers and suppliers lies not only in reducing noise around the vehicle but also in the interior. The focus is on space-saving, lightweight and multifunctional shielding systems that can be seamlessly integrated into the vehicle design. The ElroCoustic™ systems developed by ElringKlinger are the perfect solution for all applications where the priority is noise reduction. The emphasis is on minimizing vibration noise from large components and suppressing intrinsic noise.

For more information concerning our shielding systems, please got to:

http://www.elringklinger.de/en/products-technologies/original-equipment/...

Engineered Plastics

Engineered Plastics

Engineered for excellence – ElringKlinger Kunststofftechnik GmbH

The tailor-made gaskets and components developed by our subsidiary ElringKlinger Kunststofftechnik GmbH are used in a wide range of industrial applications such as chemical and equipment engineering, medical and laboratory technology, mechanical engineering and food technology. The materials used: high-performance PTFE, PTFE compounds and the newly developed thermoplastic material Moldflon™. For greater efficiency and better performance even in the toughest conditions.

For further information, please visit the website of ElringKlinger Engineered Plastics (external link).